Das Herzstück “Milk-ERP”

The Association of the German Dairy Industry (VDM) recently focused on the digitalization of company processes: in a 10-point plan, the VDM sees it as one of the most important means of maintaining and strengthening the competitiveness of the dairy industry. Practice shows: ERP (Enterprise Resource Planning) systems are usually at the heart of these digitization projects. They act as a central data platform into which other IT solutions can also be integrated.

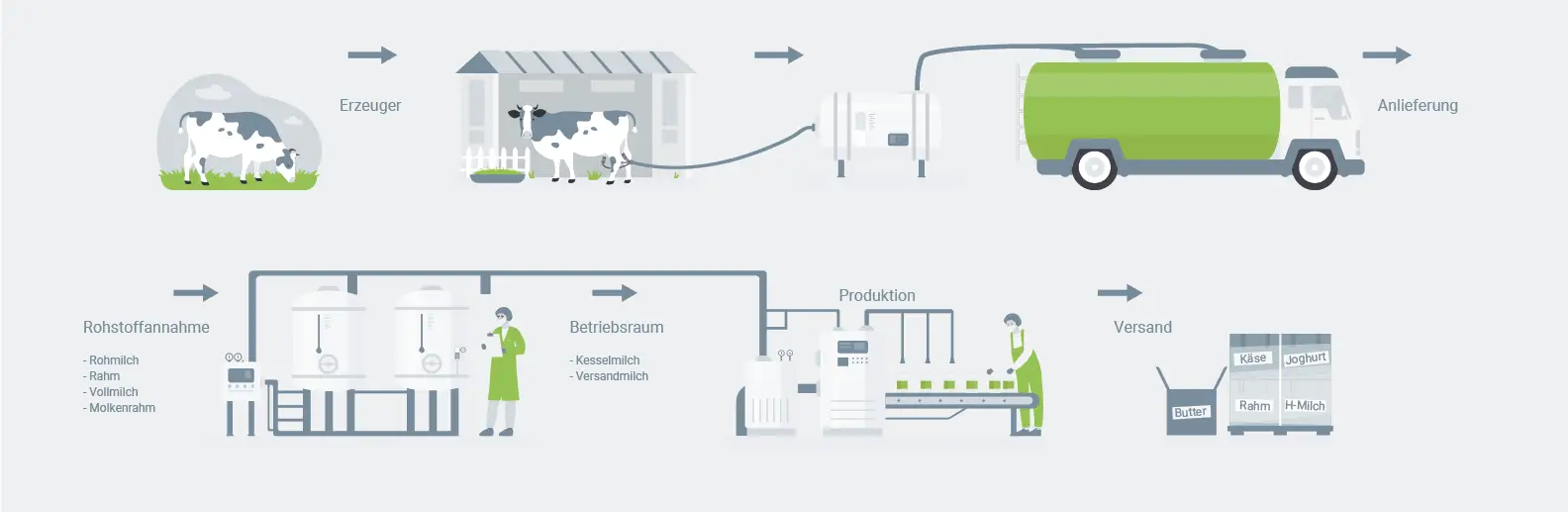

ERP systems have long been used by medium-sized and smaller milk processing companies. The goal associated with them is to enable the most comprehensive possible mapping and integration of all processes - from the collection of raw materials and production to the refrigerated counter and traceability. This is not always possible.

However, for this to be possible, ERP systems must be designed specifically for the industry. On the one hand, this means an orientation towards the general requirements of the food industry and, on the other, towards the specific processes of the dairy industry.

Wide range of functions

Furthermore, ERP solutions that offer the widest possible range of functions that can be introduced and used on a modular basis - in addition to the core ERP functions of production, purchasing, costing, warehouse management, sales, inventory management and quality assurance - are gaining acceptance. Additional components are available on a modular basis:

Additional modules

- CRM solutions for customer management

- a wide range of functions from price and condition management to contract management

- Raw material balancing and operational overviews

- Tank administrations

- Food regulations such as LMIV

- Connection of scales and scanners

- LIMS for extended QM/QA functionality

- Recipe administration and management also for product designers and developers

- Forecast and sales planning including seasonal demand calculations

- Integration of marketplaces and trading partners

At the heart of the interaction between all these individual ERP components is the workflow, which integrates and controls all tasks in the company. Company departments such as order acceptance and sales no longer work separately from each other, but operate on the basis of a common platform. In addition, the required data and information is available company-wide, standardized and at the touch of a button - and no longer in Excel spreadsheets, isolated software systems or even just in the heads of individual employees.

Digitalization therefore primarily means creating an integrated system that can be used to increase the speed and quality of company processes.

Workflow at the center

Solutions tailored to the dairy industry already deliver some workflow steps in such a way that they can be adopted 1:1. However, every company is different, which is why standard workflows sometimes have to be customized and adapted.

In the GUS-OS Suite, this is supported by the Workflow Designer - with a graphically controllable interface that makes complex process structures transparent and easy to understand and enables targeted adjustments.

Here too, the aim is to enable automation and digitalization that is as seamless as possible: Humans should no longer have to intervene in the machine. Instead, the workflows should be automated so that humans are only presented with the results.

What does such integration mean for individual employees and users? For them, the most important thing is that the tasks come to them automatically. In concrete terms: thanks to the ERP functional depth, each area, department and team member who are part of the role concept can see at a glance which tasks still need to be completed in which period and which have already been completed.

It is clear at a glance which tasks still need to be processed manually, such as placing an order. In order for this operation to be as intuitive as possible and without major training, the ease of use must be right, i.e. the ERP system not only functions as the "Internet of the company", it also follows the design and user standards common on the Internet today.

Raw material "data" is centrally available

On the basis of such an ERP system, the dairy industry in particular can benefit from a wide range of added value through further digitalization. These are only made possible by the fact that the ERP now provides a central data source and can therefore supply the "raw material" for further digitalization steps.

One example is raw milk usage planning. In many dairies today, this is done using Excel. In the digitized form, however, the expected raw milk quantity can be calculated automatically based on historical values - supplied by the ERP. Such a system can also trigger warnings if capacities are "overplanned". Or the milk quantity and ingredient negotiations: Purchasing has to conduct these regularly and compare many values and prices with each other. Excel is still often the tool of choice here too. These comparisons can also be automated with the help of data from an ERP - for example, using historical price lists or measurement results from the laboratory, which provide information about the quality of the raw materials and can be incorporated into the calculation.

Overcoming system breaks

In contrast to such ERP "internal" additional functions, digitalization today primarily means integration with third-party systems within the company or beyond - so that the data held in the system also supports the automation of processes with customers, partners or marketplaces. The main aim here is to eliminate the digital edges and gaps between the systems and to achieve integration here too. In the GUS-OS Suite, this is made possible by the Digital Hub, which extends the processes from the ERP to the relevant trading partner or farmer, for example, primarily via REST interfaces (REST, Representational State Transfer).

Here, for example, it is production that generally still offers great potential for digitalization - not so much via production suggestions, which the ERP offers as standard anyway, but in the form of automated communication of these production orders to the respective machines. This link with an MES module makes it possible, among other things, to receive feedback from the machine about the units produced, so that automation is possible.

By integrating the machines, process steps can also be tracked and documented better and in more detail. The connection of warehouse and picking systems to the ERP also offers great savings potential. For example, some customers are already using image recognition cameras to pick NVE/SSCC pallets. Such solutions also warn if there are goods on a pallet that do not belong to the current order.

With regard to external partners, other marketplaces play a major role in the dairy industry alongside the traditional food retail business. Clever integration via EDI (Electronic Data Interchange) or prefabricated Amazon interfaces, for example, can be used to extend your own processes externally in order to automate orders through to invoicing.

Digital raw materials management

Raw material management is of particular importance in the dairy industry. Companies that purchase milk from farmers may still be working with their own raw material management solution. With SOPRA's raw material management system, milk deliveries to the tank in the factory are digitized. The delivery data is analyzed after initial QM/QA samples. Once the milk is in the tank, the pre-system then transfers the so-called factory milk to the ERP as batch receipts. The delivered raw material quantities for production are already - or will be - planned.

The focus has also shifted to communication with farmers, as all key raw material management and invoicing processes must be digitized in the future. The CIS subsidiary Sopra provides the EIS portal (Producer Information System) for this purpose. It is also optimized for mobile devices such as tablets or smartphones, which offers further opportunities for integrating farmers into the dairy portal. A messaging system and closed chat groups are also integrated so that farmers have to work with fewer and fewer forms and emails.

Complex questionnaires can also be integrated - for example on quality programs or sustainability. And here too, digitalization means integrating other external partners, for example to process the relevant information with transport companies, milk exchange partners or producer advisors.