GUS-OS Suite

ERP system with vision

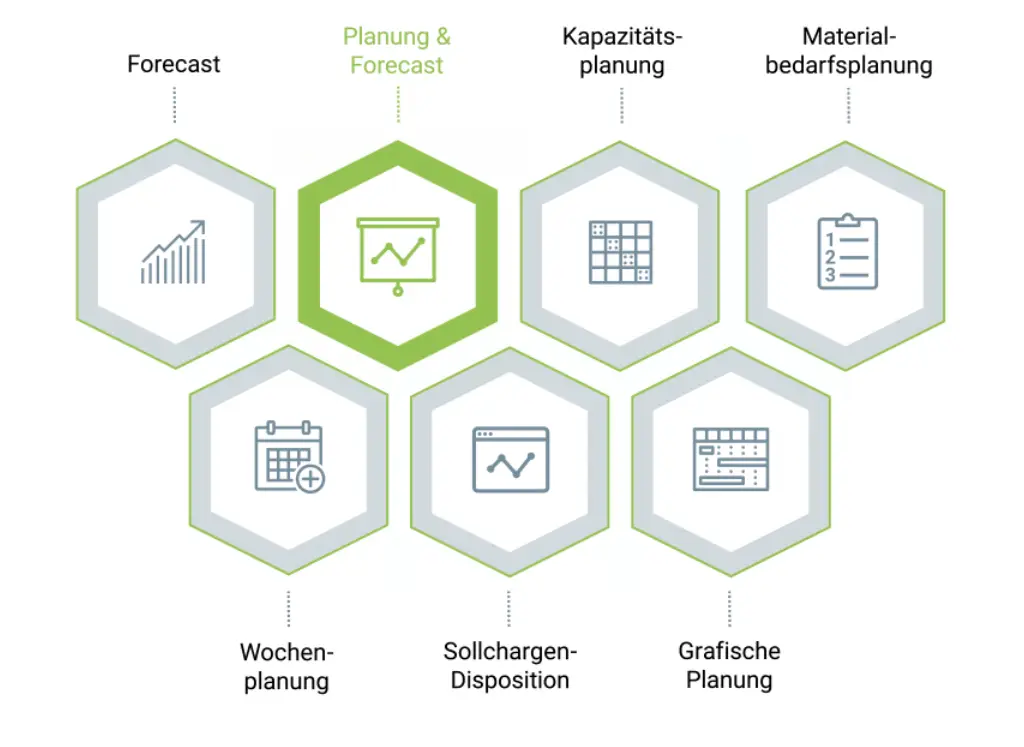

Planning & Forecast

Integrated planning with a high degree of forecasting accuracy allows processes to be controlled efficiently throughout the entire supply chain, all the way to sales, thus reducing costs. With the GUS-OS Suite, this task succeeds optimally. While the GUS-OS planning module supports material and capacity planning, the GUS-OS forecast module handles sales and sales planning as well as primary demand management. The special challenges of the process industry are accurately taken into account. Thus, capacity utilization and material requirements can be forecast, and optimization potentials also become transparent. These are the best prerequisites for maintaining your company's ability to deliver and its liquidity.

Forecast

GUS-OS Forecast supports marketing and sales activities by managing planned sales, forecasting and preparing sales plan figures and values. Sales planning is a continuous process. For this purpose, marketing and sales constantly create new planning statuses that reflect the dynamically changing planning situation or also serve specific purposes.

Capacity planning

The GUS-OS module Capacity Planning creates overviews and proposals for the time utilization of personnel and machine capacities on the basis of production orders and planning proposals for production. The aim of capacity planning is to determine and optimize the utilization of the resources available for production. For this purpose, the user is provided with various aids such as to-do lists with information on existing capacity overloads or traffic light functions for material and capacity availability. Sequence optimization readjusts selected production orders on the basis of the setup and cleaning times stored in the setup time matrix. A graphical planning board can be added to the basic capacity planning function.

Material Requirements Planning

The GUS-OS module Material Requirements Planning generates proposals for production and procurement processes with which arising stock shortages can be avoided on schedule. Based on the primary requirements - sales plan, existing customer orders and minimum stock levels - these quantities are broken down using bills of materials and taking stock levels into account. The secondary requirements determined in this way in turn result in roughly scheduled automatically generated proposals for the production of semi-finished goods and for the procurement of raw materials and packaging by purchasing. Via a to-do list, the user can directly see and process order and plan deviations with regard to material shortages and schedule deviations. With the decentralized planning, the GUS-OS Suite also offers the possibility of planning equal external locations, each with their own sales plans. It is also possible to plan external locations that are supplied from a central location. There is - in addition to demand-driven planning - the option for consumption-driven planning (also called reorder point procedure): a simple form of planning that can be optimally applied for materials with a relatively uniform consumption.

Weekly planning

With the addition of the "weekly planning" function to the Forecast module, it is now possible to record planning data at the weekly level as well, especially for more precise scheduling of tender quantities.

Target batch disposition

With the help of target batch planning, batches and orders can be linked to each other across several production stages. This makes it possible to allocate batches to the demand units in a targeted manner. Particularly in the area of sales order production, this is a suitable tool for keeping a transparent overview of the processes across the various interrelated operations (sales, production through to purchasing).

Graphic planning

The GUS-OS Planning module supplements the GUS-OS Suite with the functionalities of a planning board in a Gantt - like graphical interface. The planning board is used to graphically display the capacities / resources and their allocation by production orders / activities within the ERP system and to give the user the possibility to change them interactively. GUS-OS Planning uses the data structures of the production module of the GUS-OS Suite.

Mastering challenges in the process industry

Short development cycles, multi-stage manufacturing processes, restrictive legal requirements, strict certification requirements, and high demands on quality and environmental management: This poses major challenges for companies in the process industry and their IT systems

- especially since legal and industry-specific requirements and regulations differ from country to country and change frequently. With the GUS-OS Suite, we provide a modular solution with which companies can control complex processes across the entire value network in a consistent, integrated and yet flexible manner thanks to fully integrated workflow management. Find out how this works in our module information.

Download now!

Feature Pack 7.0 of the GUS-OS Suite

With Feature Pack 7.0, the latest version of the GUS-OS Suite is now available. Besides additional modules, it offers a multitude of new functions. Highlights of the Feature Pack are the comprehensively modernized user interface and the optimized update procedure. The GUS-OS Digital Hub Service has also been further expanded. The cloud-based service now offers extended display options as well as new, ready-made solution modules to improve communication with the field service.

Entry into digitization

The GUS-OS Digital Hub Service is a cloud-based service that allows you to individually make the processes of your GUS-OS Suite accessible outside your company. Business partners and external employees can interact directly with your ERP system, retrieve, set and update data via the web app. Get to know our Digital Hub now!